WOODWORKING

About 40% of the EU’s land area is covered by forests and this share is growing. EU forests grow with almost 700,000 hectares annually (Eurostat, 2021). In 2020, the EU had an estimated 159 million hectares of forest area, which is 10% more than in 1990 (Eurostat, 2022).

Figure 1, Overview of EU forests, own image.

Wood can be used for various purposes, including pulp and paper, furniture, and woodworking products. Woodworking includes the production of sawn wood, wood-based panels and wooden construction materials and products. The EU woodworking sector employs over a million people in 184 thousand firms. The majority of these firms are small or medium-sized enterprises (SMEs), with the exception of the sawmilling and wood-based panels sub-sectors, which are often large enterprises (European Commission, n.d. b).

Wood often has a smaller carbon footprint than other materials, as the processing of wood often requires less energy than that of other materials and because wood can retain the carbon gathered by the trees. However, the harvesting and logging of wood can potentially have their own environmental impacts. For example, improper forest management and the illegal harvesting of trees can affect the population and habitat of species living in that area, causing losses of biodiversity. Unsustainable practices and illegal logging can cause deforestation, soil erosion, droughts, wildfires and desert encroachment (Nguyen, 2017). The EU battles deforestation and forest degradation through its Forest Law Enforcement, Governance and Trade (FLEGT) Action Plan and EU Timber Regulation (EUTR), as well as through forest stewardship programs.

The woodworking sector can also have a positive contribution to the environment. The development of the woodworking sector could lead to more demand for wood products and through sustainable forest management, could lead to increases in forest area, the capture of CO2 emissions and the reversal of the effects of climate change (Iordan et al., 2018).

Figure 2, Overview of bio-based construction materials, own image

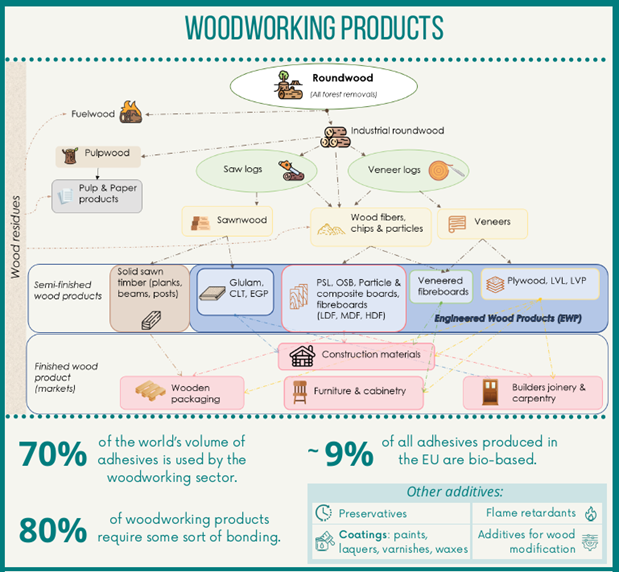

A little under half of the wood harvested in the EU is used as saw and veneer logs. These logs can be processed into solid-sawn timber products, such as planks, beams and posts, as well as engineered wood products (EWPs). Wood is a heterogeneous product, with variable properties. Especially in the construction sector, these differences in wood products can be overcome by using engineered wood products (EWP), which have a more consistent and predictable performance (European Commission, n.d. b). Engineered wood products are man-made wood products, meaning that they are created from different products such as wood fibres, sawdust, adhesives and chemicals, creating a product that can be cut and sawed like timber (Balasubramanian, 2022). Engineered wood products can be more affordable than traditional wood products, and offer benefits such as greater strength and products that are more durable. The image below shows an overview of the different woodworking products and their applications.

Figure 3, Overview different woodworking products and additives, own image.

Sawnwood are the logs sawn into different shapes and sizes, which can be used as solid sawn timber but can also be engineered to create EWPs such as glue-laminated timber (glulam) or cross-laminated timber (CLT). These products are mostly used in the construction sector. Wooden veneers, thin slices of wood, can also be used to create EWPs such as plywood and laminated veneer lumber (LVL). The parts of the logs that are not suitable for veneer, sawmill or pulp and paper processes are used as fuelwood for energy generation, or to manufacture wood-based composites. Other residues from the sector can also be used for this purpose. Wood-based composites include a variety of composite boards and fibreboards, as well as EWPs such as medium-density fibreboard (MDF), parallel strand lumber (PSL) and oriented strand boards (OSB). These EWPs can be used in construction, furniture, builders joinery and carpentry, as well as wooden packaging, such as crates and pallets (Sandberg, 2016).

The woodworking sector is already largely bio-based, as the main feedstock is wood. However, in order to make many woodworking products, additives are needed. These additives include preservatives to protect the wood against biological degradation or fire, coatings for protection or for appearance, adhesives to join wood products and give greater dimensions of wood available, and other non-wood materials to improve the performance of the product.

The woodworking sector is the world’s largest user of adhesives, with 70% of the world’s volume being used in woodworking products. About 80% of woodworking products require some sort of adhesive. The majority of additives used in woodworking are not bio-based (Sandberg, 2016). Currently, an estimated 9% of the total adhesive production in the EU is bio-based (Spekreijse et al., 2019). While glues made from animal proteins used to be common in the woodworking sector, currently synthetic adhesives are now the most common. Many synthetic adhesives use formaldehyde, a toxic substance and known carcinogen. However, there are also various other bio-based adhesives available, such as adhesives from animal collagen, dairy proteins, gluten proteins, starch crops, cellulose, and lignin (Ülker, 2016).

Most of the preservatives used for the impregnation of wood are fossil-based, of which some are known as probable carcinogens. Previously common preservatives in woodworking such as chromated copper arsenate (CCA), pentachlorophenol (penta) and creosote, are now partially banned or restricted in their use in the EU due to their toxicity to humans (Western Wood Preservers Institute, n.d.). There are also many bio-based alternatives available. Natural preservatives such as wax, shellac and drying oils can be used, as well as varnishes, lacquers and paints from a vegetable oil basis. Additionally, woodworking products can be chemically modified using furfurylation methods, in which the wood is impregnated with a mix of furfuryl alcohol and catalysts. Furfuryl alcohol is commonly produced from agricultural waste. The wood can also be thermally modified using heat and vegetable oils (van Dam & van den Oever, 2019).

In order to make sure woodworking products are produced sustainably, certifications could be required or the environmental impact can be assessed. Many buyers of woodworking products ask for sustainable forest management certifications, namely the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC). Both certifications aim at creating and implementing sustainable forest policies in order to save and protect forests against destruction (Michal, et al., 2019).

In order to assess the environmental impact of materials, products and services, a Life Cycle Assessment (LCA) can be used. LCAs can be used in the decision-making process towards sustainability and can be applied to a wide range of sectors, including the woodworking sector. As such, a case study will be performed, in which an LCA will be applied to woodworking products. The ALIGNED project will examine the environmental sustainability of a woodworking product that takes many different factors into account, such as the use of hardwood and softwood, as well as the bonding technique.

Balasubramanian, H. (2022, 11 12). Engineered wood meaning, price, and types: Decoding the popularity of this sustainable material. Retrieved from Housing.com: https://housing.com/news/engineered-wood/

European Commission. (n.d. b). Woodworking. Retrieved from Internal Market, Industry, Entrepreneurship and SMEs

Eurostat. (2021, 03 21). 39% of the EU is covered with forests. Retrieved from Eurostat: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/edn-20210321-1

Eurostat. (2022, 12). Forests, forestry and logging. Retrieved from https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Forests,_forestry_and_logging#Forests_in_the_EU

Michal, J., Brezina, D., Safarik, D., Kupcak, V., Sujova, A., & Fialova, J. (2019). Analysis of Socioeconomic Impacts of the FSC and PEFC Certification Systems on Business Entities and Consumers. Sustainability, 11(15), 4122. doi:https://doi.org/10.3390/su11154122

Nguyen, T. (2017, 12 19). Wood production, its environmental impacts and what the finnish think abou the matter. Retrieved from Globe: http://globetamk.weebly.com/blog/wood-production-its-environmental-impacts-and-what-the-finnish-think-about-the-matter

Sandberg, D. (2016). Additives in Wood Products: Today and Future Development. Environmental Impacts of Traditional and Innovative Forest-based Bioproducts, 105-172. doi:https://doi.org/10.1007/978-981-10-0655-5_4

Ülker, O. (2016). Wood Adhesives and Bonding Theory. In A. Rudawska, Adhesives – Applications and Properties. InTech. doi:10.5772/65759

van Dam, J., & van den Oever, M. (2019). Catalogus biobased bouwmaterialen. Wageningen University.

Western Wood Preservers Institute. (n.d.). Preservatives Used Today. Retrieved from Preserved Wood: https://preservedwood.org/the-story/todays-wood-preservatives